Replacing silicon and organic substrates with glass requires a massive transformation in the manufacturing industry, and the challenges it brings will take years to resolve.

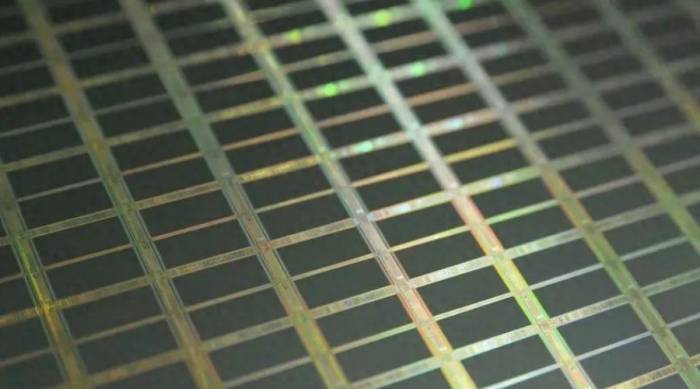

The chip industry is racing to develop advanced glass packaging, paving the way for one of the biggest changes in the field of chip materials in decades - a change that will introduce a series of new challenges that will take years to fully address.

For more than a decade, glass has been discussed as an alternative material to silicon and organic substrates, mainly used for multi-chip packaging. However, as Moore's Law gradually fails, the transition from planar chips to advanced packaging has become an inevitable trend for cutting-edge designs. The current challenge is how to build these devices more efficiently, and glass has become a key driver at the forefront of packaging and lithography technology. Intel announced last year that it will launch glass substrates later this decade. The US government has allocated $75 million to Absolics, a subsidiary of South Korea's SKC, under the US "Chips Act" to build a 120,000 square meter factory in Georgia for manufacturing glass substrates.

"The advantages of glass are obvious," said Rahul Manepalli, a fellow and director of Intel's Substrate TD Module Engineering Department. "But the problems you need to solve include interface stress, understanding the fracture dynamics of glass, and understanding how to transfer stress from one layer to another."

As substrates become thinner to meet the requirements of modern semiconductor devices, the brittleness of glass is particularly problematic. Handling and processing these thin glass substrates requires great care and precision, as the risk of damage significantly increases.

Advertisement

Glass also makes detection and measurement more difficult. "We are transitioning from the typical small field lithography based on wafers to other technologies," said Keith Best, Director of Lithography Product Marketing at Onto Innovation. "When using glass, simply scaling up is not enough. It requires a low numerical aperture (NA) lens system that can achieve the necessary depth of focus in a larger area without losing resolution."

In addition, large wafer fabs and OSATs (Outsourced Semiconductor Assembly and Test) have already made substantial investments in other materials, such as copper-clad laminated panels. These materials have been field-proven as substrates in PCBs, but they will gradually lose their advantages as the packaging industry develops to below 2/2 nm line width/pitch. Transitioning to glass requires new equipment investment and new processes, or it needs to be integrated with existing processes."Currently, there is no formula that allows us to create a dedicated production line for glass substrates," said Yin Chang, Senior Vice President of ASE Group. "There is currently no business to support this. It either adapts to standard processes, or it will take longer."

Why glass, and why now?

Despite these obstacles, the industry widely recognizes the transformative potential of glass panels and the likelihood of their eventual widespread adoption. Glass offers excellent dimensional stability, as well as the ability to support larger areas and finer patterns. It also has the same coefficient of thermal expansion as silicon and is extremely flat and stable.

"Glass is definitely a trend," said Doug Shelton, Marketing Manager at Canon. "Glass is very forgiving and has some advantageous electrical properties. As long as they do not try to make it particularly thin, glass can make lithography simpler."

One of the most attractive features of glass is its low dielectric constant, which can minimize signal propagation delays and crosstalk between adjacent interconnects, which is crucial for high-speed electronic devices. It can also reduce the capacitance between interconnects, thereby accelerating signal transmission and improving overall performance. In applications where speed is crucial, such as data centers, telecommunications, and high-performance computing, using glass substrates can significantly improve system efficiency and data throughput.

The low dielectric constant also makes impedance control better, ensuring signal integrity throughout the circuit. This is particularly attractive in RF applications, where impedance matching is crucial for maximizing power transfer and minimizing signal loss. By providing consistent electrical properties on the substrate surface, glass substrates facilitate the design and manufacturing of high-frequency circuits, improving reliability and performance.

Another key advantage of glass substrates is their excellent thermal stability, which plays a vital role in maintaining the performance of devices under fluctuating thermal conditions. Unlike copper-clad laminates that may deform or delaminate under thermal stress, glass substrates exhibit minimal dimensional changes over a wide temperature range. In applications where thermal management is crucial, such as automotive electronics, aerospace systems, and industrial control, the ability of glass to maintain dimensional integrity under thermal cycling helps prevent electrical shorts, open circuits, or other reliability issues typically caused by mechanical strain due to temperature.

"We expect glass to be adopted first in a data-centric world, especially in AI/ML-based packaging," said Manepalli from Intel. "This application will immediately bring performance benefits."

The thermal stability of glass substrates also simplifies the design and implementation of advanced packaging solutions, allowing for tighter component integration and higher packaging density. By eliminating concerns related to substrate warpage or deformation, glass substrates enable more precise alignment of chip components, smaller interconnect spacing, and improved overall system performance."It will be very interesting to see how these glass materials enter the ecosystem of these complex devices, both at the substrate level and at higher levels of integration," said David Fromm, Chief Operating Officer of Promex Industries.

Process Improvements

Another significant advantage of glass substrates is their exceptional flatness, which is crucial for panel-level lithography processes, where precise alignment and feature consistency are essential for achieving high-resolution patterning. Glass substrates ensure consistent focal plane alignment during the lithography process, enabling the creation of fine-pitch interconnects and complex circuit patterns with greater precision and repeatability.

Moreover, the flatness of glass substrates improves the yield and reliability of semiconductor devices by reducing the occurrence of defects such as pattern distortion or misalignment. This, in turn, leads to higher manufacturing yields and improved overall device performance, especially in applications requiring strict tolerances and high integration.

The shift to glass also supports the process flow. Glass exhibits predictable behavior under various processing conditions, reducing process variables. Engineers can fine-tune their processes around a material that responds reliably and consistently, enhancing production line efficiency and predictability—once the processing issues are addressed.

"Glass panel processing requires meticulous precision," Best added. "But once you master your process, this material will work with you, not against you."

A significant challenge of glass substrates in lithography is their inherent fragility, which becomes particularly pronounced as the industry moves towards thinner substrates to meet higher device integration and performance requirements. Glass panels with thicknesses often reaching 100 micrometers or thinner pose significant risks during handling and manufacturing processes. Glass is prone to cracking or breaking under stress, highlighting the need for specialized equipment and processes to safely manage this material.

"Glass substrates have their own set of challenges," said Brad Perkins, Director of Product Line at Nordson Test & Inspection. "When you see those large glass panels reaching over 500 millimeters square, you encounter some real challenges, such as how much they will bend and deform, and then how do you secure them?"

To address this fragility, handling systems must match the complexity of the lithography technology itself. Advanced packaging companies are actively exploring robust handling, vacuum, and mechanical support systems to transport and handle these fragile glass panels without breakage. Additionally, innovations in soft handling techniques for loading and unloading substrates in lithography equipment are being pursued to mitigate the risks associated with handling fragile glass substrates."Thin glass substrates are extremely fragile and require careful handling," said Best from Onto, "They demand fineness, precision, and most importantly, innovation in handling techniques. You must move it very carefully. For example, when you put it into the plating tank, the stirring and turbulence of the plating tank may cause it to break."

Hybrid Substrates

Glass can also be combined with traditional substrates, allowing existing methods to utilize the thermal stability and electrical advantages of glass while taking advantage of the mechanical robustness and mature manufacturing processes of materials such as organic laminated panels or silicon interposer substrates. The result is a substrate with outstanding overall performance indicators that can meet the diverse needs of contemporary and future chip designs.

For instance, hybrid substrates may adopt a glass core for low-loss, high-frequency signal transmission, combined with copper-clad laminated panels (CCL) to enhance structural rigidity and cost-effectiveness. This synergistic combination can mitigate some of the challenges associated with glass, such as brittleness, while leveraging its high-performance characteristics.

"The combination of glass with other substrates is not just about combining the advantages of the two," said Best from Onto, "It is about obtaining performance characteristics that we have never seen before."

Standardization and Compatibility

A significant obstacle to the adoption of glass panels is the lack of a unified standard for the size, thickness, and characteristics of glass substrates. Unlike silicon wafers that follow precise global specifications, glass substrates currently lack universally accepted dimensions and characteristics. This lack of standardization brings complexity to equipment manufacturers striving to produce universally compatible tools and semiconductor factories seeking to interchange substrates without significant process adjustments.

Closely related to standardization is the issue of compatibility, which exists not only between different batches of glass substrates but also between the substrates and the semiconductor devices they support. The unique electrical and thermal characteristics of glass must be carefully matched with the characteristics of the semiconductor devices."Glass won't be used on mature products," added Chang from ASE. "It will be used in the most advanced applications, providing better power solutions. But it will be more difficult to handle. This is one of its key issues."

As the semiconductor industry moves towards advanced packaging methods, such as chip modules and 3D-IC, significant changes are happening in the back-end processes. This shift involves adopting and adapting methodologies that are traditionally associated with front-end semiconductor manufacturing.

Lithography now plays a key role in creating line widths below 2µm, which is necessary for the adoption of chip modules and 2.5D/3D-IC packaging. However, these finer dimensions also require materials that can withstand more stringent processing conditions while maintaining structural and functional integrity.

"The biggest challenge we face is to get the most out of lithography tools as possible," said Travis Brist, Senior Product Manager at Synopsys. "While there has always been such a push, it is becoming more critical."

Due to fewer restrictions on the substrate format in packaging, and the ability to use larger lenses and lower numerical apertures, packaging suppliers are turning to fan-out panel-level packaging (FOPLP) to process more packages on a single panel, thereby reducing costs. It is estimated that the cost of panels can be reduced by 30% to 40% compared to 300mm wafer fan-out.

Innovation

Given the larger size and different physical properties of panels compared to silicon wafers, achieving fine-pitch interconnects required for advanced packaging requires lithography technology that can produce smaller feature sizes on panel substrates without sacrificing alignment accuracy. This is particularly challenging on larger panels, as warpage becomes an issue that must be considered during the lithography process.

Due to its durability, robust mechanical properties, and cost-effectiveness, copper-clad laminated board (CCL) has always been the preferred substrate material for FOPLP. Its composition makes it a durable choice for the harsh environment of semiconductor packaging processes, and the relative affordability of glass fiber and copper also promotes its widespread adoption.However, the structure of CCL, which endows it with strength, also makes it prone to warping under the thermal and mechanical stresses common in FOPLP. Each layer of the substrate may produce a slightly different overlay deviation, which is a complex situation caused by panel deformation. This deviation must be strictly controlled because it can lead to challenges in maintaining consistent line patterns and feature sizes. Even minor differences can lead to significant yield loss and affect the overall efficiency of the package.

In addition, minor changes in the surface electrical properties of the CCL substrate can affect signal integrity and overall device performance, especially in high-frequency applications.

"Copper-clad laminated board is very robust, but when it comes to warping and deformation, it is very unstable," said Best from Onto. "But most people are still using CCL now. They have reached the level of 9/12 [nano lines/spacing] and are considering the possibility of reaching 5/5. Some people even want to push it to 2/2, but this may be the limit of CCL. Then the race to transition to glass begins."

Compatibility involves not only the physical properties of the glass but also the adhesion of other materials used in the semiconductor stack (such as dielectric materials and metals), which may behave differently on glass than on traditional substrates.

In the absence of industry standards, performance differences also become a common challenge. As each manufacturer adheres to its proprietary specifications for glass substrates, a situation arises where products from the same company may perform differently from those of another company in the same application.

As advanced packaging moves towards finer pitches and more complex interconnection technologies, the differences in thermal expansion coefficients and electrical properties between glass and other materials in the stack become increasingly important. Without standardization, integrating glass with technologies such as Through-Silicon Vias (TSVs) and microbumps will be fraught with complexity, potentially affecting yield and reliability.

To address these challenges, industry-wide collaboration is needed to establish and adopt standards for glass substrates. This collaboration involves working groups composed of glass manufacturers, semiconductor companies, packaging experts, and equipment suppliers, who work together to develop reliable standards to improve the predictability and efficiency of the manufacturing process.

As glass substrates seek to play a central role in future advanced packaging, standardization and compatibility will be crucial. Only through industry collaboration and reaching a common agreement can the full advantages of glass substrates be realized.

ConclusionBy leveraging glass panels, manufacturers can break through the limits of interconnect density, paving the way for more complex and closely packed integrated circuits. Not only do devices become smaller and faster, but also, due to the uniformity of the substrate's electrical properties, device performance becomes more reliable, maintaining consistency across batches.

"There is still a lot of potential in glass that we haven't even scratched the surface," Maneppalli added. "We haven't even tapped into the high-frequency advantages of glass. Imagine what we could create with glass and its properties once we've mastered the process."